ADI-IS designs and manufactures its own endoscopic devices enabling an appropriate technical answer to specific needs.

INDUSTRY CHALLENGES FOR HOT BLAST AIR CIRCUIT

Efficient uninterrupted operations of hot blast air supply to the blast furnace -> RELIABILITY

SStable process conditions avoiding fluctuations since there is no room for mistakes -> CONSISTENCY

Low costs operations and down time minimization -> RETURN ON INVESTMENT

Energy efficiency -> LOW EMISSIONS

SOME (VERY) GOOD REASONS TO PERFORM ENDOSCOPY WITH ADI-INDUSTRIAL SERVICE

COOLING ELEMENTS

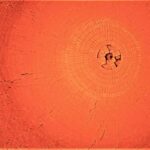

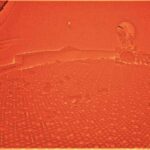

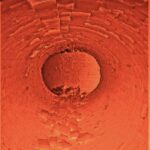

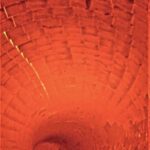

Efficient cooling staves are aiming to balance the thermal load and associated wear of the inner refractory lining of the furnace, and consequently to protect the shell. The efficiency of the cooling systems of a BF plays a key role in an extended campaign life of a BF and hence the operating costs. Cooling staves are subject to significant thermal loads changes which may lead to stave failures due to cracks, water leakage, bending, abrasion and resultant wear. The pictures, recorded during endoscopic inspection, show how lime scales can damage the inner part of the water piping, leading to poor cooling, wear and possible water leakage.

REFERENCES